Mineral Processing Support app for iPhone and iPad

Developer: Magotteaux

First release : 21 Aug 2018

App size: 29.82 Mb

Mineral Processing Support – by Magotteaux is a quick reference tool providing a practical troubleshooting and support guide as well as useful calculators for metallurgists and plant operators.

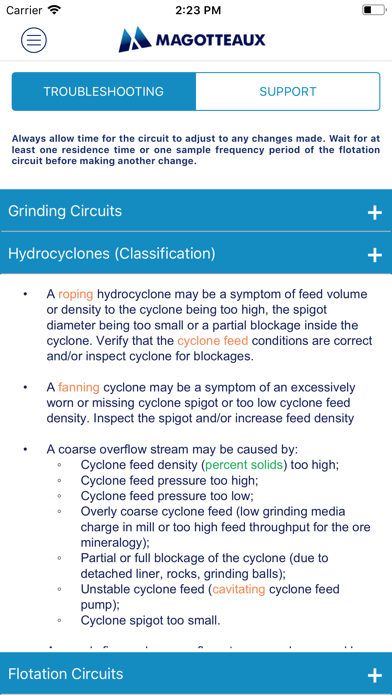

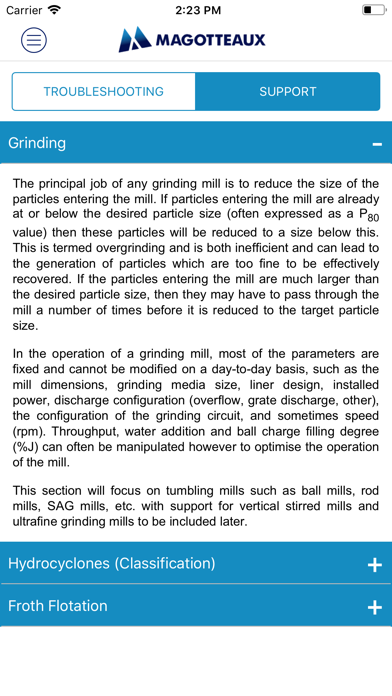

This app has been designed by Magotteaux’s grinding and flotation specialists to give the user useful information relevant to their normal duties, or when responding to operational problems in the plant. Dot point troubleshooting guides are clear and concise, making them easy to follow when trying to generate a corrective action plan for a particular plant issue. Support for common plant processes provide the user with a fundamental understanding of the operation of grinding mills, cyclones and flotation circuits. Calculators covering a range of fundamental tasks from the plant to the metallurgical laboratory are included and are designed to easily input data and clearly display the result.

Always available offline allowing the user the freedom of using the app while trying to resolve an issue in the plant.

GRINDING MILL SUPPORT

* Operation fundamentals

* Grinding mill power draw

* Media filling degree

* Media consumption

HYDROCYCLONE SUPPORT

* Cyclone operation

* Particle size distribution (PSD)

* Underflow and overflow streams

FROTH FLOTATION SUPPORT

* Poor recoveries

* Poor concentrate grade

* Pulp density control

* Froth depth control

* Reagent addition

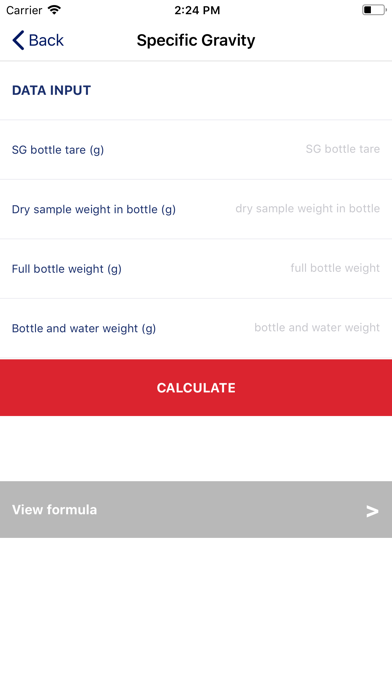

CALCULATORS TO DETERMINE

* Media filling degree

* Mill critical speed

* Percent solids

* Percent passing sieve size

* Circulating load (cyclone)

* Specific gravity

* Reagent addition rate conversions

* Recovery (2 product formula)

* Element to mineral conversions

This app is designed to offer support to the user, but not to in anyway replace or undermine the site’s operational standards, practices and safe work procedures. Recording any changes made to the plant, including the time, as well as informing the plant supervision of any changes is highly recommended.